Metallurgy

Characterization of the structure and the properties of the interfaces in metal matrix (nano)composites

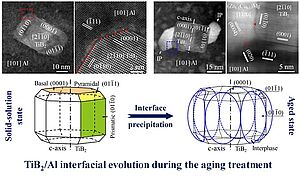

Metal matrix (nano) composites (NMMCs) are promising candidates in many engineering fields because of their ability to combine the best mechanical and functional properties within each other. Such NMMCs are characterized by a high interface to volume ratio and marked differences in properties between the (nano-) reinforcements (TiB2, carbon nanotubes (CNTs), diamond, graphite) and the metallic matrix (Al, Cu and Ti). De facto, their properties are determined not only by the charge transfer and energy exchange mechanisms through the matrix/nano-reinforcements interface, but also by new mechanisms favored through an area affected by the interface. In this project, a microstructural and multiscale characterization essentially by means of electron microscopy in corrected transmission Cs and scanning electron microscopy and in-situ tests (mechanical and temperature) will be carried out to clarify the characteristics related to the area affected by the interface and also the localized properties of this interface (Ma et al., 2019, Xu et al., 2019, Li et al., 2017, Tan et al., 2016, Ji et al., 2016).

Gang Ji (MPGM-UMET), Ahmed Addad (UMET), Rajashekhara Shabadi (MPGM-UMET), Vincent Ji (Université Paris-Saclay, France), Williams Lefebvre (Université de Rouen, France), Hanlin Liao (UTBM, France), Jean-François Silvain (Université de Bordeaux, France), Kim Vanmeensel (KU Leuven, Belgique), Nick Schryvers (Université d’Anvers, Belgique), Sasan Dadbakhsh (KTH Suède) Zhe Chen (Université Jiao Tong de Shanghai, Chine), Zhiqiang Li (Université Jiao Tong de Shanghai, Chine), Xiaopeng Li (UNSW, Australie), Tim Sercombe (UWA, Australie), Mingxing Zhang (Université de Queensland, Australie)

Microstructural characterization of novel High Entropy Alloys

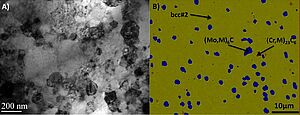

Unlike conventional alloys, high entropy alloys are made up of a large number of elements (4, 5, 6 ...) in almost equimolar proportion. Despite complex compositions, these new materials only consist of a reduced number of phases (solid solutions) with remarkable properties. The MPGM team at UMET is interested in the development and characterization of such alloys in as yet unexplored systems. Thus, it synthesizes, by mechanical alloying followed by sintering, an alloy in the new Al-Cr-Fe-Mn-Mo system. The body centered cubic structure and the composition of the new phase were determined by MET / EDS. Due to carbon contamination coming from the process, carbides have also formed in the material. They were identified by MET. In addition, a combined EBSD / EDS analysis made it possible to determine the size distribution of each of the phases and thus to describe more precisely the microstructure of the material. (Stasiak et al., 2019).

Matthieu Touzin (MPGM-UMET), Franck Béclin (MPGM-UMET), Catherine Cordier (MPGM-UMET), Tomasz Stasiak (MPGM-UMET)

Conception and characterization of graded Fe based metallic matrix composites reinforced with yttria stabilized zirconia

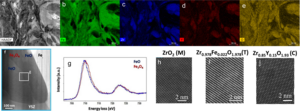

A graded Fe based metallic matrix composite reinforced with yttria-stabilized zirconia was developed by powder metallurgy comprising high-energy ball milling, compaction and sintering. The milled sample is polycristalline and nanocomposite with a Fe grain size in-between 5 and 10 nm. The grain size of monoclinic zirconia and YSZ reinforcementsis lower than 200 nm with a mean value of 20 nm as shown in the EDX maps in the figure (a)-(e). Solid state sintering entailed (i) the growth of Fe grains, which remained submicrometric, and (ii) the coarsening of oxides reinforcements forming an interconnected network in the bulk graded composite. The reinforcements in the bulk sample were of different natures, namely tetragonal yttria stabilized zirconia, monoclinic zirconia, wüstite, magnetite and to a less extent, Zr0.978Fe0.022O1.978 (tetragonal) and Zr0.85Y0.15O1.93 (cubic) (figure (f)-(j)). The increase of oxide reinforcement’s volume fraction enabled to obtain a material with a graded electrical resistivity and a slightly graded hardness; the bending resistance of the as-developed material has however decreased because of the weakness of the reinforcements – matrix bonds (Naji et al., 2019).

Kaoutar Naji (MPGM-UMET), Marie-Noëlle Avettand-Fènoël (MPGM-UMET), Mathieu Touzin (MPGM-UMET), Maya Marinova (PMEL), Philippe Pouligny (SNCF Saint Denis)